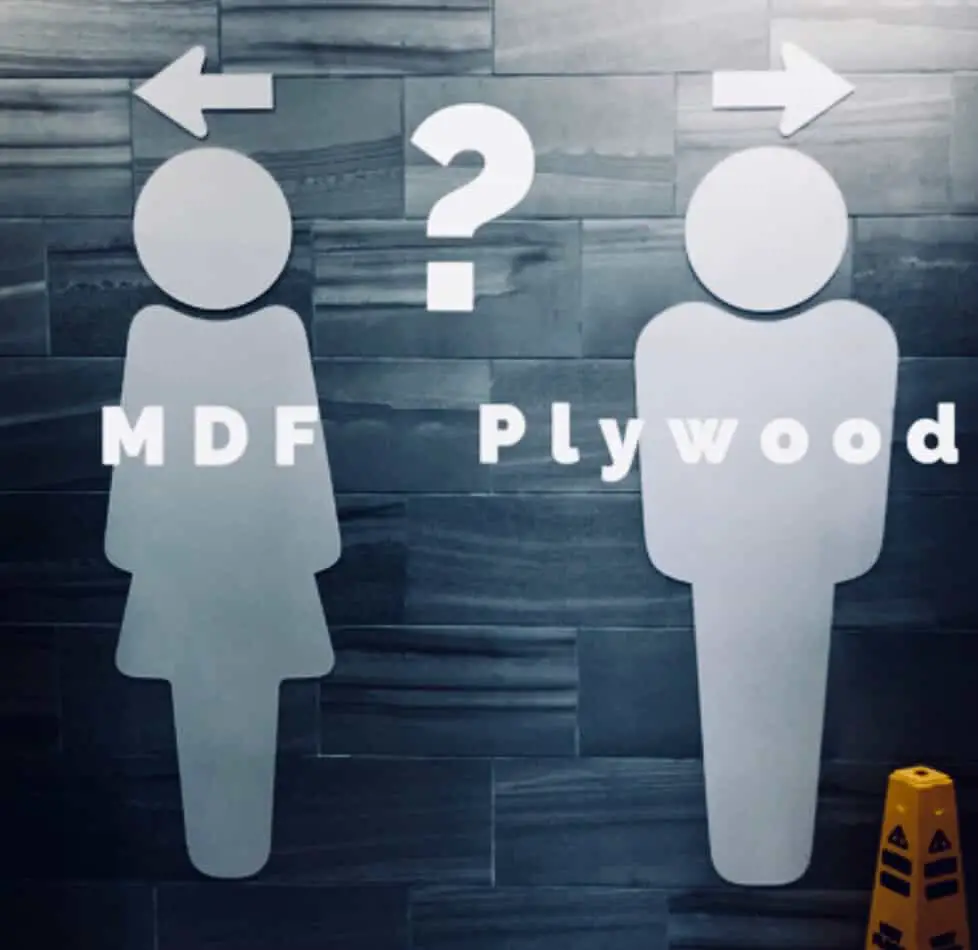

I have done a lot of researching on the use of MDF vs. plywood for a desk. There are of course advantages and disadvantages both ways but the bottom line is this:

MDF offers smoother, straighter surfaces than plywood. You have to keep water away from it and its strength compared to plywood is a topic of debate, but for the right applications, it can be a great option. Let’s look further into this and see if MDF is the right material for you to use in your build

First, a common Misconception. MDF is not particle board. It’s stronger than particle board. When cut it is easy to tell the difference between the two as MDF is much denser. Particle board will appear to have a lot of open spaces, air pockets essentially when you cut into it and look at a cross-section. I do realize there are similarities between the two but they are not the same. MDF is generally a better building material and for our purposes here, we are talking about MDF, not particle board.

A common use for MFD is in shelving. The reason for this is that the boards are straight, smooth, and consistent. The material is also becoming increasingly common in lower-cost furniture, especially those that you order online and assemble yourself. You can obtain MFD in different finishes and veneers so it’s possible to build your desk with MDF and have a more traditional “wood look” similar to a stained hardwood at a much cheaper cost.

There is also an environmental argument for MDF. Since the material is made from wood fibers that are common leftovers from woodworking, many believe that this extra step in recycling alone is a worthy consideration. Whatever your motivator, the question before us is whether or not MDF is a viable building solution for your desk PC project.

Is medium-density fiberboard superior to other wood materials?

MDF is a common go-to material for fabricating projects such as desks. It’s generally very consistent in texture as opposed to its alternatives which often have grain variations and surface imperfections. It also usually paints well with a consistent finish. Some variations can even be stained.

As for whether you should use MDF as your building material when constructing your Desk PC, it really comes down to personal preference, cost considerations, and experience with woodworking.

When my son and I built his desk PC, I chose to use 1/2 inch plywood that came pre-sanded on one side. Partially because I felt that plywood would be a better material and partially because, frankly, it was available at my local lumber yard. To use MDF I would have had to drive an hour to a Lowe’s or Home Depot. In the end, it worked out fine but if I had it to do over again I think I would have used MDF, at least for the bottom.

Hindsight is 20/20

You see, we chose to wrap the inside bottom of the case with a vinyl carbon fiber design. We love the way the RGB lights reflect off of it and it looks amazing.

The problem we ran into however was that plywood has a lot of irregularities in its surface due to the grain. I had thought originally that the vinyl wrap would hide those imperfections. What it actually did though was to highlight them. The dents and ridges showed through and when the led lights hit them it was like a flashing neon sign saying “look at this – this looks like crap!”

We ended up tearing the original wrap off and spending a ridiculous amount of time spreading wood putty into the cracks and sanding them to get a clean look. We could’ve saved a tremendous amount of time had we just used MDF.

It is important to note, however, that MDF is often reported as not having the strength that plywood does in the same thickness. A wide desk may suffer from bending or sagging if additional bracing is not built in to offset this but to be honest we ran into the same problem with our plywood (although in fairness we used 1/2 inch and should have used 3/4). Still, strength does need to be considered in the equation.

Note: There are arguments against the strength factor all over the internet and it is difficult to find consensus. MDF manufacturers, in particular, argue that MDF is actually stronger than plywood. This is an understanding position for those who stand to benefit financially from its use. But there are woodworkers with seemingly comparable expertise who are 180 degrees apart on this and I find that to be a little perplexing.

Maybe we should just split the difference and assume, for our purposes here, that they are somewhat equal in strength until someone resolves this with a definitive and inarguable experiment.

Beyond the strength consideration, there are two primary cautions that I would offer regarding MDF.

The first is that the sawdust from MDF is toxic. In 2016, the National Center for Biotechnology Information (NCBI) published an in-depth study into the effects of exposure to MDF composite materials during the manufacturing process. The study focused on a plant in Thailand where a significant amount of MDF was manufactured. The study found that formaldehyde concentrations were over three times the OSHA standard acceptable levels.

The U.S. Consumer Product Safety Commission published a review of the progress being made toward the reduction of formaldehyde in 2013 and cited an 80-90% reduction in levels found in MDF comparable to the 1980’s so we are definitely seeing the results of public concern and governmental oversight. You may recall the $36 million settlement that resulted from unacceptable formaldehyde levels in wood flooring products from Lumber Liquidators.

The bottom line here is to use a respirator and work in a well-ventilated area (good advice regardless of the material chose).

Second, water is to MDF as kryptonite is to Superman. If you are planning to incorporate liquid cooling into your build then you will want to be mindful of this as you fill your reservoirs and conduct leak tests.

Health concern issues aside, when it comes down to making a determination on MDF as a viable building material for a Desk PC case, I would have no reservations in using it for a build so long as care was taken with these caveats in mind. Ultimately there are pros and cons to every building material. So long as it meets your needs and you are well informed of the potential downfalls, use the material that you feel comfortable using. I’d much rather see you focus on designing your dream desk PC and actually building it than to get bogged down with the MDF dilemma.

Diffen has an excellent comparison on MDF vs. Plywood if you really want to delve into this further.

So, are you ready to start building that amazing desk PC yet? If so, let’s start designing.